Filmic Contaminations

Filmic Contaminations hinder join technologies like Gluing or Welding, lead to leaks or affect the coatablilty of surfaces in a negative way. These film-like contaminations result from residues of chemicals used in the production process as for instance oils, high viscosity greases, cooling lubricants or residues of the cleaning process like surfactants. In many cases, the concentration of filmic contaminations is inhomogenously distributed onto the surface with concentration hotspots at edges and surface topographies. In certain cases, the presence of filmic contaminations has damiging character only at defined locations, e.g. in the area of adhesive joint. The analysis of filmic contaminations is subdevided into local and integral methods.

RIO Cleanalytic Services offers the analysis of filmic contaminations via GC-MS, FTIR and contact angle measurements. Please do not hestitate to contact us!

Local Methods

Determination of Surface Tension

Determination of the surface tension can be done very simplified by the usage of test inks. Therefore, a surface area of several cm2 and a trained operator is mandatory. Contamined surfaces show low wettability, clean surfaces on the other hand are characterized by high surface wettability. Test inks are based on the assumption that the free surface energy matches with the surface tension of the test ink offering the best wettability. In reality, surfaces often contain polar and disperse portions of the surface energy especially if they were optimized for gluing or coating processes via plasma or flame treatment.

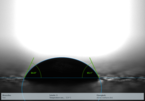

Determination of Surface Energy

Determination of the surface energy is possible via contact angle measurements. At the same time, two drops are disposed onto the surface using a polar fluid (e.g. water) and a disperse fluid (e.g. Diiodomethane). Based on this two-component system information on the adhesion behaviour and the interfacial surface tension can be extracted from the data correlating to the long-term stability. An area of only few mm2 is needed for the test. Uneven surfaces cannot be measured using this technique.

Fluoresence Test

Most filmic contaminations show fluorescent characteristics upon UV-excitation. The intesity can be correlated to the concentration or amount of the contamination as far as a reference for a clean surface is available. The size necessary can be reduced to 1 mm in diameter. Due to the local measurement, the inspection can be limited to the area of interest.

Integral Methods

Cleaning and Anlysis via GC-MS, FTIR or Raman-Spectroscopy

Cleaning of the component (completely or in the relevant surface area) and analysis of the (non-particular) residues detached from the surface can be analysed gaschromatographic combined with mass spectroscopy (GC-MS) or after solvent evaporation via Fourier-transform infrared spectroscopy (FTIR) or Raman-Spectroscopy. The procedure is relatively undependant on the geometry of the component and offers the chemical composition of the filmic residues. In a qualitative way, the amount of the contamination can be calculated. The result corresponds to the average over the cleaned surface area.

Vacuum Testing via Residual Gas Analysis

Application of a vacuum causes desorbtion of highly volatile compounds. The method is able to quantify the amount of desorbing hydrocarbons (regardless of adsorbed or absorbed) and is able to identify the chemical composition. The result corresponds to the average over the cleaned surface area.